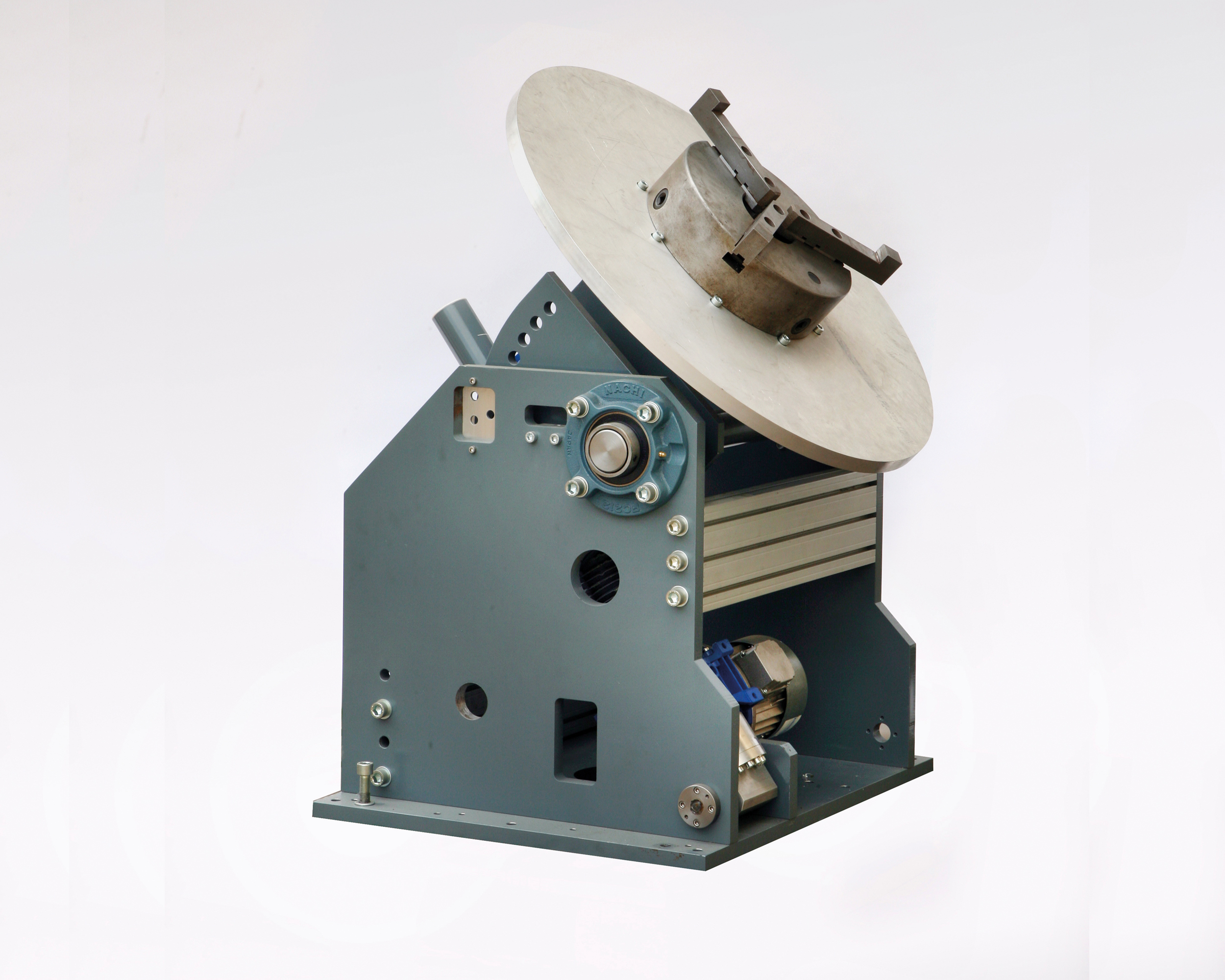

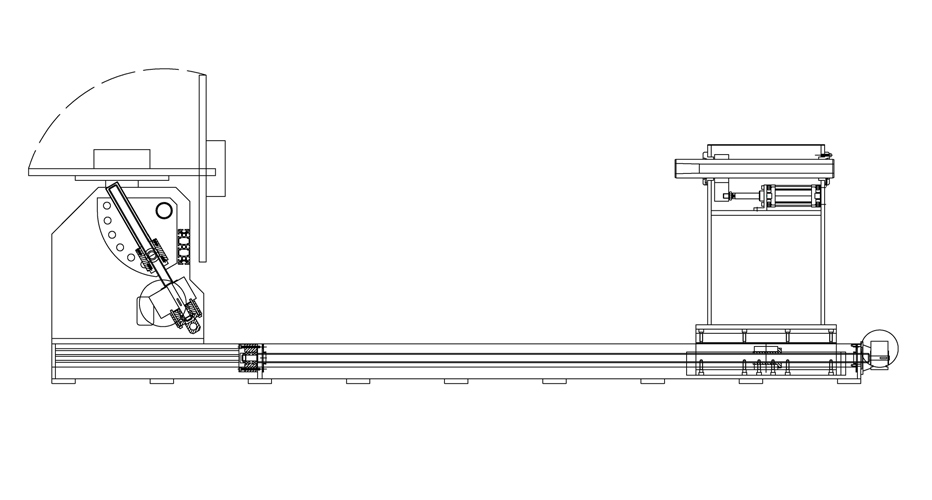

Tilting Table

Free to move

Some coating processes need particular work-piece’s handling that can be performed by a tilting table. The tilting table has two axes which can be directly driven by the robot control as external axes.

Lincotek Equipment is able to create a fully-customized the tilting table that best suits your needs: size, weight, handle, spindle (single or multi-chuck), and more…

Generally the tilting table can rotate from 10 to 300 rpm and tilt from 0° to 90°. As an option the tilting table can be extended to a multifunction spray lathe.

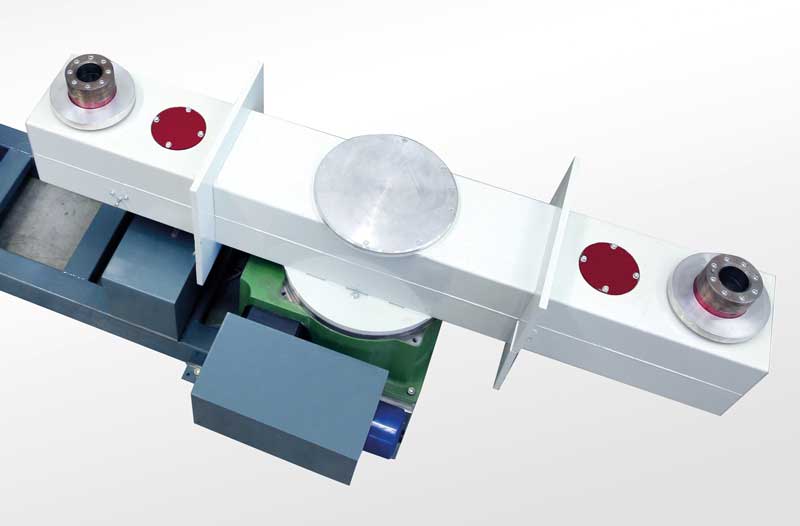

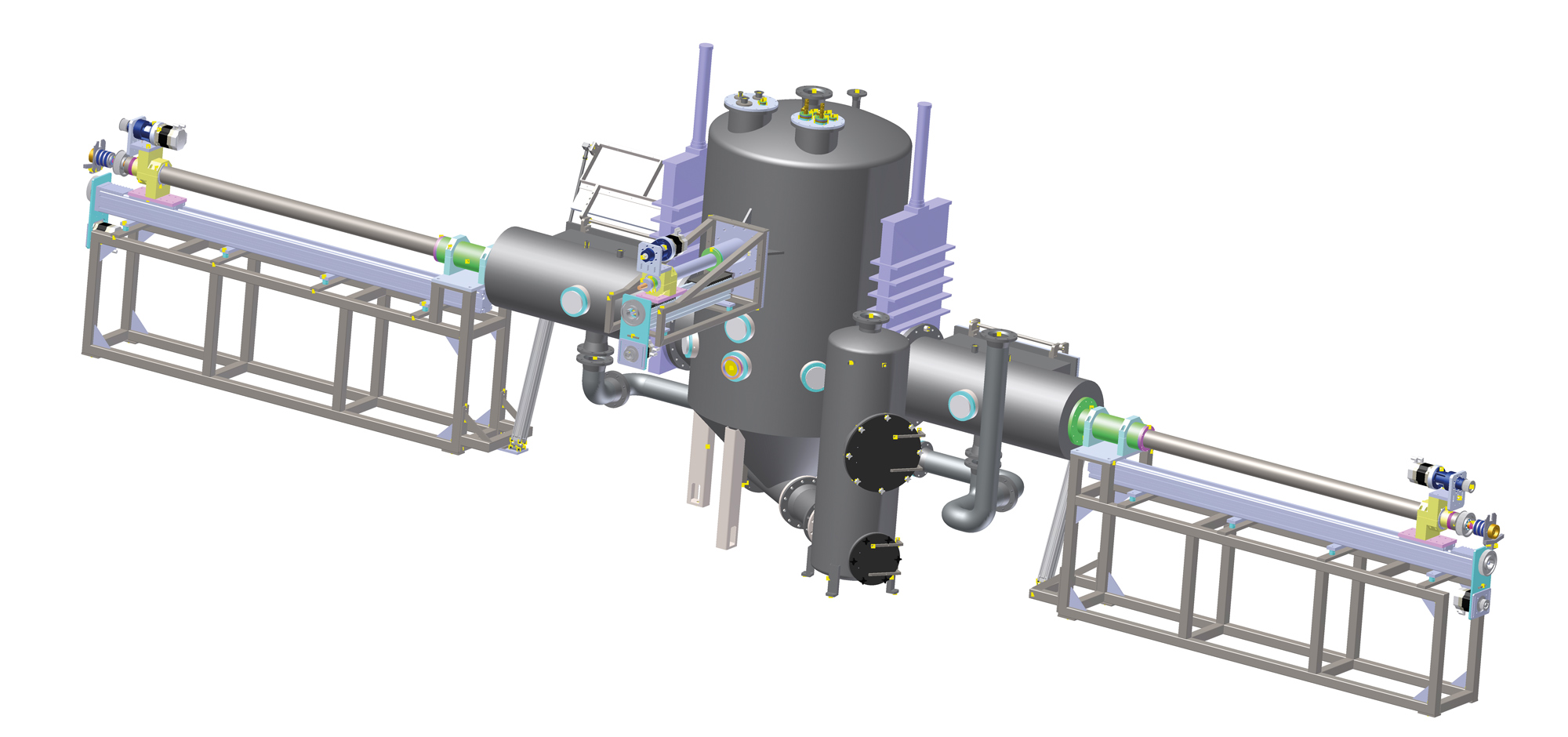

Carousel

The carousel has been designed to save time and improve productivity.

The carousel has been designed to carry the work pieces inside and outside the sound-proof booth that performs the coating. This reduces machine downtime to bare minimum. While a piece is under coating, another one can be positioned to be ready, it saving time and improving productivity.

Do you need something special for your company? Custom solutions are our main business. We have experience of creating Carousels with between 2 and 12 positions, customized on demand.